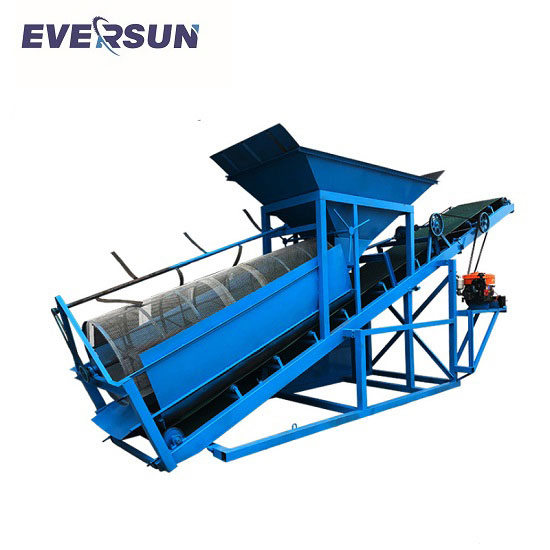

Maximize Material Testing: High-Performance Screener for Sale

Wiki Article

Increase Recycling Performance With High-Quality Screener Equipment

In the mission to attain greater performance in recycling processes, one can not underestimate the relevance of utilizing high-grade screener devices. These innovative screening devices use an array of benefits that not only enhance material splitting up capability yet additionally increase arranging speed and enhance accuracy in product category. Allow's explore the complexities and capability of high-quality screener devices to discover the tricks behind their success.Improved Product Separation Ability

With its improved product separation ability, the high-grade screener equipment substantially boosts the efficiency of recycling processes. This ability permits the tools to accurately separate different materials based on their form, density, and size, causing an extra streamlined recycling operation.One of the essential advantages of the improved product splitting up capacity is the capacity to different recyclable products from non-recyclable waste better. By efficiently segregating materials such as plastics, metals, paper, and glass, the screener equipment guarantees that important resources are not squandered and can be reused or repurposed. This not only lowers the amount of waste sent to land fills however additionally saves natural deposits, making the recycling process much more sustainable.

In addition, the enhanced material splitting up capability of the top quality screener equipment enhances the total top quality of the recycled materials. By creating cleaner and higher-quality recycled materials, the screener tools contributes to an extra effective and successful recycling sector.

Boosted Arranging Speed

One trick aspect of the top notch screener tools is its capability to handle a larger volume of materials in a shorter quantity of time. This is made possible by the usage of high-speed electric motors and effective conveyor systems that can transport products quickly and smoothly with the testing procedure. By reducing the moment it requires to arrange products, the devices boosts overall reusing effectiveness.

Moreover, the top quality screener devices incorporates innovative sensing units and arranging systems that can properly recognize and separate various types of materials. These sensing units can detect variants in shape, dimension, and density, enabling the equipment to promptly and exactly different recyclables from non-recyclables - screener for sale. This not only quicken the sorting procedure but additionally enhances the high quality of the apart products

Improved Accuracy in Material Category

Better accuracy in material classification is an essential element of high-quality screener devices for improving reusing efficiency. Accurately recognizing and sorting different kinds of products is essential for effective recycling processes. By using innovative modern technologies and innovative screening methods, top notch screeners can attain better accuracy in classifying materials, resulting in enhanced recycling results.One of the crucial advantages of improved accuracy in product category is the capacity to different recyclables from non-recyclables extra successfully. screener for sale. With precise category, beneficial products can be recognized and removed from the waste stream, lowering contamination and raising the total recycling return. This not only makes the most of the resource recovery potential yet additionally lessens the quantity of waste that ends up in landfills

Furthermore, accurate product category allows the identification of particular types of recyclable products, such as plastics, steels, or paper items. This enables targeted reusing procedures, where various products can be processed separately, causing higher-quality recycled discover this info here items. Additionally, boosted precision in material classification aids to satisfy the strict top quality criteria set by reusing markets, guaranteeing that the recycled materials fulfill the required specifications for reuse.

Lessened Downtime and Maintenance

To make certain ideal operational performance, premium screener equipment is made to reduce downtime and reduce the requirement for frequent upkeep. This is achieved with using long lasting and robust elements, progressed modern technology, and thoughtful design factors to consider.One way that top quality screener tools lessens downtime is by integrating self-cleaning devices. These systems aid avoid obstructing and blockages, which can cause downtime and costly maintenance. By instantly removing particles and ensuring smooth material circulation, these self-cleaning attributes allow the devices to run continuously without disruption.

In enhancement, top quality screener devices frequently consists of integrated diagnostics and monitoring systems. These systems can discover possible concerns and sharp operators before they intensify right into significant troubles. By offering real-time details regarding the problem of the tools, drivers can take aggressive measures to decrease and prevent breakdowns downtime.

Additionally, top notch screener tools is made with simplicity of upkeep in mind. Elements that need regular upkeep, such as screens and belts, are quickly available and easy to replace. This reduces the moment needed for upkeep tasks, allowing operators to obtain the tools back up and read the article running swiftly.

Greater General Recycling Productivity

One way top quality screeners increase recycling efficiency is by minimizing the requirement for hands-on sorting. These makers are furnished with sophisticated sensors and intelligent software that can automatically identify and separate recyclable products based upon their make-up, shape, and size. This eliminates the labor-intensive and taxing job of hands-on sorting, allowing reusing centers to process bigger quantities of materials in less time.

Furthermore, high-quality screeners can take care of a vast array of materials, consisting of large and irregularly designed items. They are made to stand up to heavy lots and are outfitted with resilient screens that can successfully separate products of different sizes. This adaptability enables reusing facilities to handle a higher variety of waste products, maximizing their functional efficiency.

Additionally, premium screeners are equipped with functions such as adjustable screening setups and automated cleaning devices. These features permit operators to enhance the testing process for various materials, making sure optimal effectiveness and decreasing downtime.

Final Thought

To conclude, premium screener tools is important for enhancing recycling efficiency. It uses enhanced material separation ability, boosted arranging rate, and improved accuracy in product category. Additionally, it minimizes downtime and maintenance, causing higher total recycling productivity. By purchasing such tools, have a peek at this website reusing facilities can enhance their procedures and add to an extra sustainable future.

It provides improved material separation ability, boosted arranging rate, and boosted precision in product category.

Report this wiki page